Swivel Coupler

Price 20000 INR/ Ton

Swivel Coupler Specification

- Technique

- Other

- Weight

- Approx. 1.15 kg Kilograms (kg)

- Constitute

- other

- Features

- High strength, corrosion resistant, allows angular connection, reusable

- Color

- Silver / Yellow

- Product Type

- Swivel Coupler (Scaffolding Clamp)

- Material

- Carbon Steel / Malleable Cast Iron

- Components

- Other

- Diameter

- 48.3 mm Meter (m)

- Width

- Standard 50 mm Meter (m)

- Length

- 110 mm Meter (m)

- Height

- 60 mm Meter (m)

- Thickness

- 5 mm Meter

- Platform Loading Capacity

- Up to 6 kN Gram (g)

- Surface Treatment

- Electro-galvanized / Hot Dip Galvanized

- Application

- Scaffolding tubes connection at any angle

- Size

- 48.3 mm x 50 mm x 110 mm

- Angle of Rotation

- 360

- Bolt Dimensions

- M12 x 60 mm

- Usage

- Building construction, maintenance, industrial scaffolding

- Operating Temperature Range

- -30C to +60C

- Torque Requirement

- 50 Nm

- Packaging

- 25 pcs per bag / Gunny bundle

- Clamping Force

- Minimum 14 kN

Swivel Coupler Trade Information

- Minimum Order Quantity

- 100 Pieces

- Supply Ability

- 20 Pieces Per Week

- Delivery Time

- 1 Week

About Swivel Coupler

Relying upon the highly developed premises, we are affianced in distributing a broad arrangement of Swivel Coupler. It is fabricated with a progressive techniques and innovative tools to improve its excellent finishing. This coupler is admired for its sturdy installation and long lasting effect. Swivel Coupler is used the connect the two objects in both vertical as well as horizontal direction. It is resistant to corrosion and water. It has a forged body to withstand easily in higher loads.

Reliable and Durable Design

Engineered from carbon steel or malleable cast iron, and finished with either electro-galvanization or hot dip galvanization, the swivel coupler is designed to withstand heavy-duty usage and resist environmental wear. Its zinc-plated fasteners and sturdy drop-forged construction ensure longevity, even under demanding conditions.

Exceptional Versatility for Scaffolding Systems

The 360 rotation enables flexible and secure angular connections, making it ideal for intricate scaffolding assemblies. Whether in construction, industrial maintenance, or as a supplier solution, the couplers adjustable angle supports efficient, tailor-made scaffold configurations for complex sites.

Simplified Installation and Reuse

Installation requires only a 50 Nm torque on the M12 x 60 mm bolt, allowing for precision and safety with every use. The couplers robust design means it can be reused multiple times without compromising performance, providing cost savings and sustainability for recurring projects.

FAQs of Swivel Coupler:

Q: How is the swivel coupler installed onto scaffolding tubes?

A: To install the swivel coupler, align it with two 48.3 mm diameter tubes at the desired angle. Tighten the included M12 x 60 mm bolt with a torque wrench to 50 Nm, ensuring a secure connection. The drop-forged steel design allows for easy and reliable assembly in various configurations.Q: What are the main benefits of using this swiveling coupler in construction projects?

A: This swivel coupler provides high strength, corrosion resistance, and versatile 360 rotation, allowing tubes to be joined at any angle. Its robust construction and high loading capacity (up to 6 kN) ensure safety and reliability across scaffolding systems, while its reusable nature offers cost-effectiveness in long-term projects.Q: When is it recommended to use a swivel coupler over a fixed coupler?

A: Swivel couplers are best used when scaffolding tubes need to be joined at non-parallel or varying angles, such as in diagonal bracing, geometric platforms, or complex architectural scaffolds. Use a fixed coupler for linear, right-angle connections instead.Q: Where can this swivel coupler be effectively utilized?

A: This coupler is ideal for building construction, industrial scaffolding, and maintenance projects. It is suitable for both indoor and outdoor environments, thanks to its corrosion-resistant finish and wide operating temperature range of -30C to +60C.Q: What process is used to manufacture the main body of the coupler?

A: The main body of the swivel coupler is manufactured using a drop forging technique, which imparts superior strength and durability. The steel is forged and subsequently treated with either electro-galvanization or hot dip galvanization to prevent corrosion.Q: How does the packaging and quantity of the coupler contribute to project efficiency?

A: Each package contains 25 swivel couplers, making them easy to transport and distribute on construction sites. The bulk packaging reduces handling time and supports fast assembly when building large scaffold structures.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Scaffolding Accessories Category

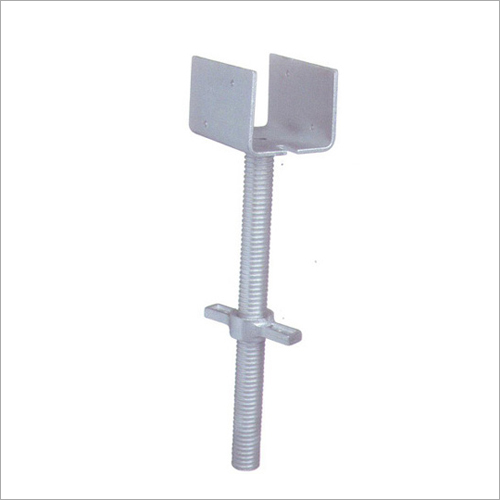

Adjustable U Head

Price 80000.00 INR / Ton

Minimum Order Quantity : 100 Pieces

Technique : Other

Material : Other , Mild Steel

Components : Other

Surface Treatment : Other, Galvanized, Painted, Powder Coated

Drop Head

Price 80000 INR / Ton

Minimum Order Quantity : 20 Tons

Technique : Forged

Material : Other , Mild Steel

Components : Other

Surface Treatment : Other, Painted and Powder Coated

Adjustable Base Plate

Price 78000 INR / Ton

Minimum Order Quantity : 100 Pieces

Technique : Other, Hot Rolled

Material : Other , Mild Steel (MS)

Components : Other, Base Plate, Adjustable Screw, Nut

Surface Treatment : Other, Galvanized / Painted

Castor Wheel

Price 80000 INR / Ton

Minimum Order Quantity : 100 Pieces

Technique : Other

Material : Other , Mild Steel (Bracket), PU (Tread), Polypropylene (Wheel Core)

Components : Other

Surface Treatment : Other, Zinc Plated

|

MARUTI STEEL FAB

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry